Automotive Injection Molding & Precision Manufacturing

From prototype to high-volume production — we deliver reliable, cost-effective automotive plastic parts with zero compromise on quality.

- Partnered with leading global automakers

- IATF 16949 & ISO 9001:2015 certified

- 24/7 technical support with <1-hour response

Automotive Parts Manufacturing Capabilities

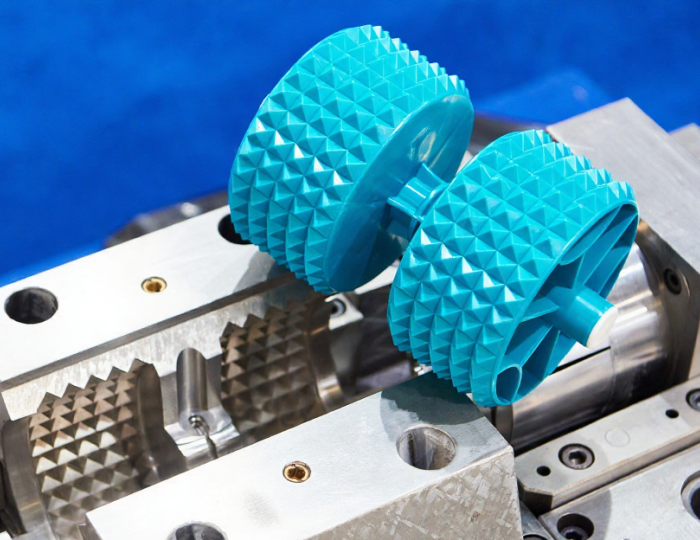

Plastic Injection Molding

High-volume plastic injection molding for automotive parts, ensuring dimensional accuracy, repeatability, and production efficiency.

Rubber Injection Molding

Rubber injection molding for automotive seals and gaskets using TPE and TPV materials for durability and flexibility.

CNC Machining

Precision CNC machining supports automotive prototyping, tooling components, and low-volume parts requiring tight tolerances.

Overmolding

Overmolding enables multi-material automotive components, combining rigid plastics with elastomers for functional designs.

Why Choose Livepoint

We deliver precision, compliance, and reliability for custom medical components across regulated global markets.

- Trusted by Leading Automotive Brands

Our molds support global OEMs and Tier suppliers, delivering consistent quality for luxury, electric, and high-volume automotive programs, helping customers reduce supply risk and maintain stable production. Renowned clients include Ferrari, Tesla, and Volkswagen.

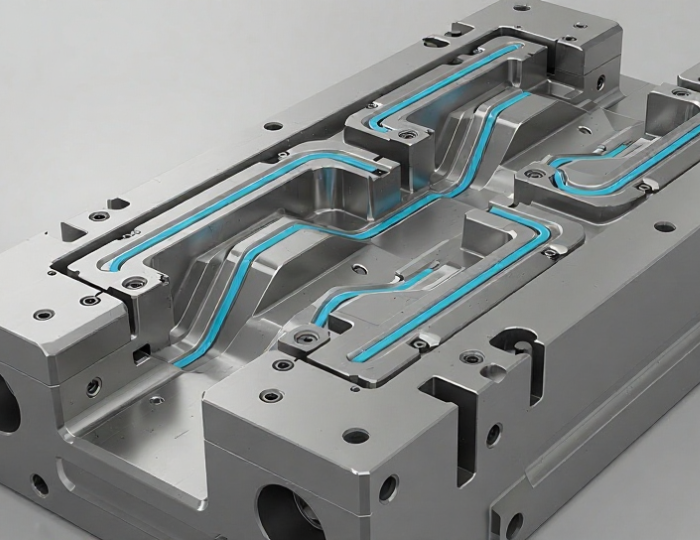

- Tooling Expertise

Livepoint has deep expertise in multi-cavity molds and hot runner systems, enabling efficient and repeatable manufacturing of complex automotive plastic components with shorter cycle times and lower unit costs.

- Production Precision

Our advanced 3D CAD design and CAE flow analysis ensure tight tolerances, accurate part fit, and consistent quality across demanding automotive production runs, reducing defects and rework.

500 Million

Parts Manufactured

200+

Customers Served

95%

of Leading Brands Served

Precision-Molded Automotive Components

High-quality, high-volume solutions for interior, exterior, lighting & under-the-hood systems

We deliver precision-molded automotive parts with tight tolerances, Class-A surfaces, and stable mass production — helping you reduce costs, accelerate time-to-market, and meet OEM quality standards.

Interior Components

Dashboards, air vents, control buttons, knobs, decorative trims, cup holders.

Under-the-Hood Components

Fluid reservoirs, engine covers, sensor housings, air intake and fluid management components.

Exterior Components

Front grilles, headlamp and tail light housings, wheel arch liners, bumper supports.

Lighting Components

Injection-molded housings and lenses for interior and exterior automotive lighting systems.

Materials for Automotive Parts

We support automotive projects with application-specific material selection to meet mechanical, thermal, and regulatory demands.

Bumpers, body panels, exterior trim

PP

Lightweight, chemical-resistant, and cost-effective. Common for bumpers and exterior claddings needing impact strength.

PC / PC-ABS Blends

Used for grilles, mirror housings, and wheel covers. Combines heat resistance, strength, and surface quality.

ABS

Ideal for bright trim components like chrome-plated grilles. Smooth surface ensures excellent plating compatibility.

Headlights, lenses

PC

Dominant for headlamp lenses. High impact resistance and clarity. Requires hard coating for UV and scratch protection.

PMMA

Used for interior lenses or reflectors. Excellent optical clarity and UV resistance, but brittle for exterior applications.

Engine covers, air intake, fluid management

Nylon

High heat and chemical resistance. Maintains strength and stiffness under demanding engine conditions.

PP

Heat-resistant grades for battery cases and fluid reservoirs.

POM

Precision parts like clips, gears, and connectors. Low friction, high stiffness, and dimensional stability.

Dashboards, trim, consoles

ABS / PC-ABS

Strong, heat-resistant, and smooth finish for painting or texturing. Widely used for dashboard skeletons, glove boxes, and panels.

PP

Economical choice for A/B/C pillar trims, glove box doors, and battery cases.

ASA

UV-resistant alternative to ABS, used for interior and exterior trim. Maintains color and durability in sunlight.

Seals, gaskets, bellows

TPE / TPV

Replaces traditional rubber for seals and gaskets. Easier to process and recyclable.

PU

Tough, abrasion-resistant, used in suspension bushings, seat foam, armrests, and concept car body panels.

Consistent Automotive Quality Trusted by Leading OEMs

Livepoint has extensive experience in automotive tooling and injection molding, delivering precise, durable, and stable production for world-renowned brands such as Ferrari, BMW, Tesla, and Volkswagen.

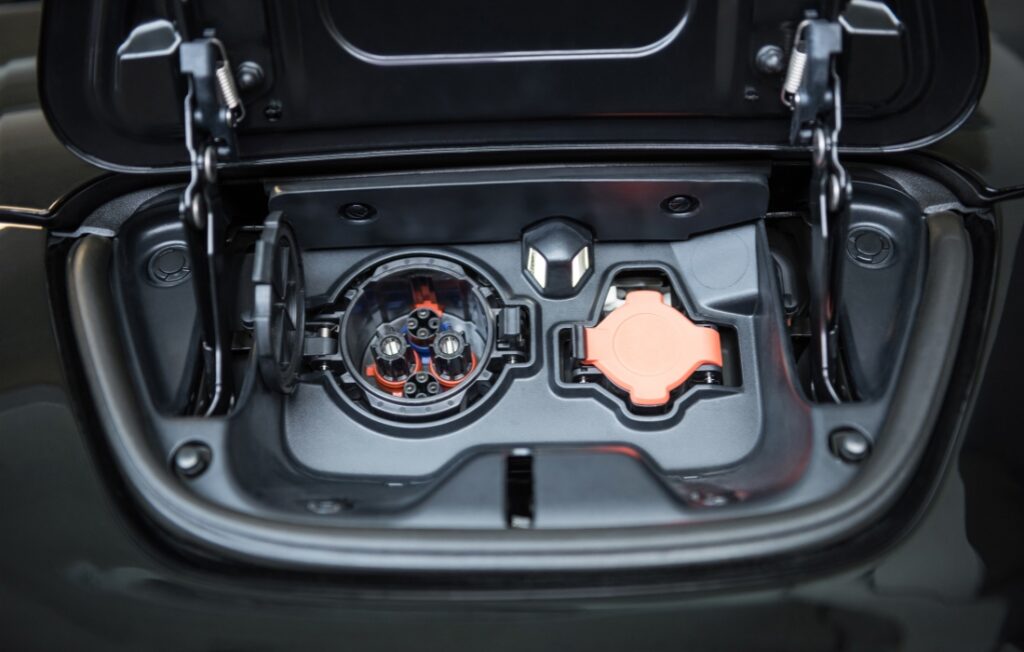

Precision tooling support for automotive charge port components, with tight tolerance control to ensure reliable fit and stable assembly performance in production.

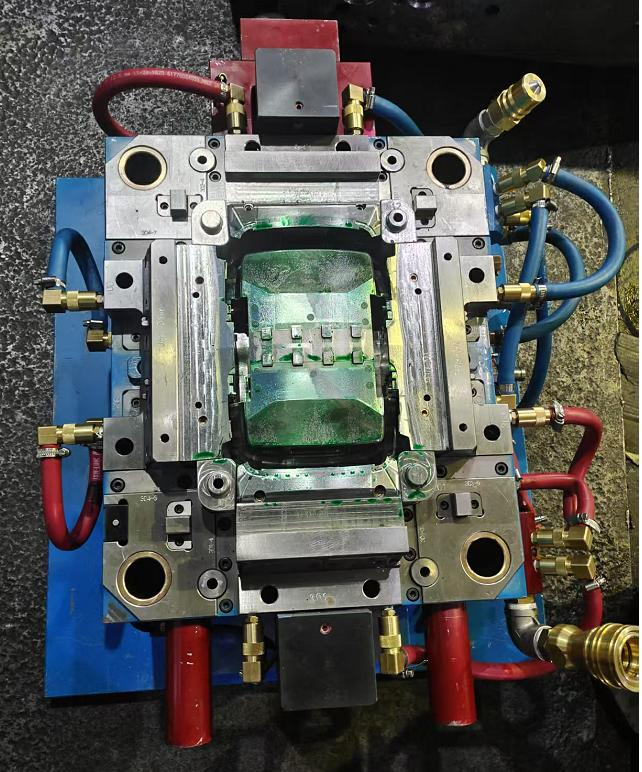

Precision tooling and injection molding for automotive parts, utilizing controlled processes and durable materials to maintain consistent part quality.

Precision tooling and injection molding for automotive parts, utilizing controlled processes and durable materials to maintain consistent part quality.

1th Floor, Building C, Hengshunyuan Industrial Park,No. 6, Louyi Road, Loucun Community, Xinhua Street, Guangming District, Shenzhen City, Guangdong Province, China

Automotive Injection Molding FAQs

We support a wide range of automotive OEMs and Tier suppliers across different vehicle segments, including:

- Luxury & Performance: Ferrari, BMW, Mercedes-Benz

- Electric Innovation: Tesla, BYD, Li Auto

- Global Volume Brands: Volkswagen, Peugeot, Honda

This experience enables us to meet diverse technical, quality, and production requirements.

Yes. We offer in-house mold design and manufacturing, giving us full control over tooling quality, lead time, and long-term performance throughout the production lifecycle.

Absolutely. Our molds are engineered for durability and repeatability, supporting stable, high-volume production and long-term automotive programs with consistent quality.

Material selection is driven by a balanced evaluation of key engineering and production factors, including:

- Weight: Supporting fuel efficiency and vehicle performance

- Cost: Suitability for large-scale production

- Performance: Strength, impact, heat, and chemical resistance

- Aesthetics: Paintability, texture, and surface finish

- Manufacturability: Process stability and molding efficiency

We help customers select materials that meet both functional and commercial goals.