Consumer Electronics Injection Molding & Manufacturing

Micron-level precision combined with scalable, high-volume production. Livepoints help transform complex designs into reliable, market-ready consumer electronics.

- IATF 16949 & ISO 9001:2015 certified

- Trusted by global brands

- 23+ years in precision tooling

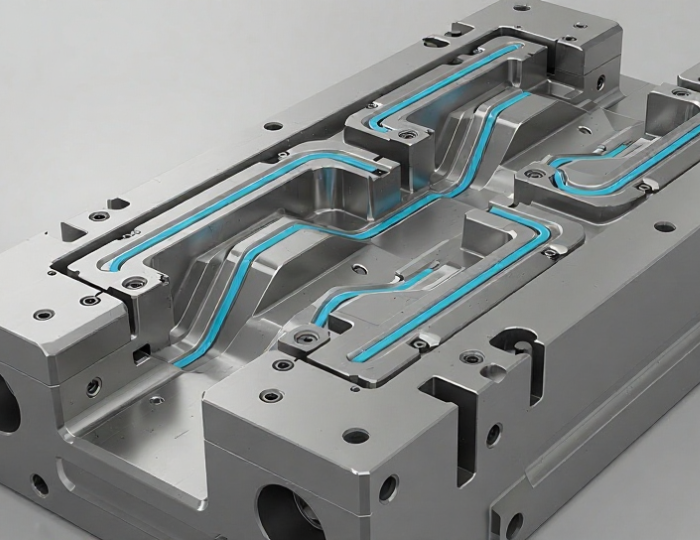

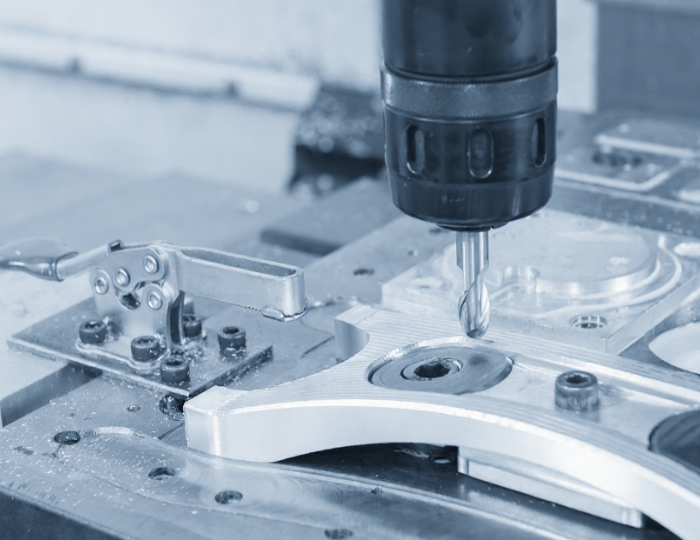

Manufacturing Capabilities for Consumer Electronics

LSR Molding

Produces high-heat resistant, flexible seals, gaskets, and keypads with excellent durability, consistency, and tactile performance.

Overmolding

Combines rigid substrates with TPE or TPU to enhance ergonomics, protection, durability, and overall user experience.

Two-Shot Molding

Enables precise multi-material integration for soft-touch grips, functional interfaces, and durable, seamlessly bonded sealing structures.

Micro-Molding

Delivers micron-level precision for miniature components used in wearables, IoT devices, connectors, and micro-optical assemblies.

Why Choose Livepoint

We help leading consumer electronics brands scale complex products with confidence, combining proven engineering, advanced tooling, and smart manufacturing execution.

- Trusted by Global Brands

LivePoint has supported global brands including Amazon, Dell, Siemens, Sony, TCL, KONKA, Changhong, and Skyworth, delivering stable quality and on-time production for high-volume consumer electronics programs.

- Engineering Depth & Innovation

We have hands-on experience manufacturing 75-inch and 100-inch TV housings, managing large-tonnage machines, tight flatness control, cosmetic surface quality, and structural stability at scale.

- Smart Manufacturing

Through real-time mold sensing, Moldflow validation, and connected factory systems, we reduce process variation, prevent defects early, and maintain consistent quality across long, high-volume production runs.

500 Million

Parts Manufactured

200+

Customers Served

95%

of Leading Brands Served

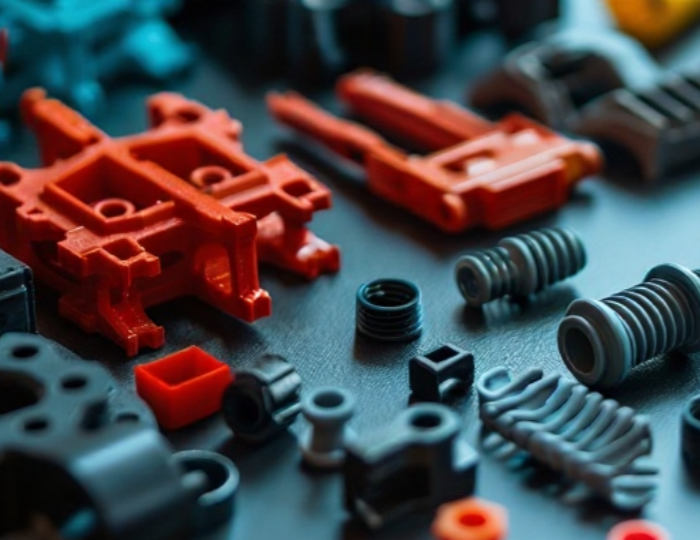

Consumer Products We Can Manufacture

We manufacture high-precision plastic components for a wide range of consumer electronics, balancing aesthetics, structural integrity, and scalable production.

Mobile Devices & Wearables

Smartphone housings, watch cases, fitness tracker bands, internal brackets.

Audio Products

Earbud casings, headphone sliders, speaker grilles, and acoustic chambers.

Laptops & Computer Peripherals

Thin-and-light laptop chassis, keyboard frames, touchpad modules, and mouse enclosures.

Smart Home & IoT Devices

Sensor housings, router casings, connector components, and camera bodies.

Portable Chargers & Power Banks

Durable, aesthetically pleasing enclosures.

Materials for Consumer Products

We work with a broad range of engineering polymers, including high-performance materials offering EMI/RFI shielding, static control, and UL94 V-0 flame retardancy.

ABS

Cost-effective material with excellent surface finish, impact resistance, and paintability for housings and interior structural components.

PC

High impact strength and optical clarity, ideal for transparent parts, thin-wall enclosures, and heat-resistant electronic housings.

Nylon

Strong, wear-resistant material offering excellent mechanical strength and thermal stability for functional and load-bearing components.

PEEK

Ultra-high-performance polymer with exceptional heat resistance, chemical stability, and mechanical strength for demanding electronic applications.

Customer Testimonial

“Their expertise in micro-tolerances and material science was critical for the success of our latest wearable device. They are a true extension of our engineering team.”

— Director of Product Development, Leading Tech Company

1th Floor, Building C, Hengshunyuan Industrial Park,No. 6, Louyi Road, Loucun Community, Xinhua Street, Guangming District, Shenzhen City, Guangdong Province, China

Consumer Electronics Injection Molding FAQs

We provide high-gloss, matte, and textured surfaces to meet aesthetic, functional, and brand requirements for electronic housings and components.

We produce intricate parts with undercuts, snap-fits, and multi-material combinations, enabling complex designs for modern consumer electronics.

From raw material certification to final inspection, we implement Statistical Process Control (SPC), first-article inspection, and rigorous testing to ensure every component meets strict specifications.

Yes. Our advanced CNC machining, EDM, and CMM inspection produce molds with tolerances within ±0.01mm, ensuring consistent, high-precision parts production.

We provide ultrasonic welding, precision assembly, laser etching, and cosmetic painting to deliver fully finished sub-assemblies ready for market.

Yes. We support a seamless transition from 3D-printed prototypes to full-scale production, enabling rapid iterations and high-volume manufacturing of millions of parts.