Injection Molding Solutions for New Energy Applications

Livepoint delivers precision injection molding for mission-critical new energy components, including EV battery systems, charging infrastructure, and energy storage applications.

- IATF 16949 & ISO 9001:2015 certified

- 24/7 engineering support

- 23+ years in precision tooling

Manufacturing Capabilities for New Energy Application

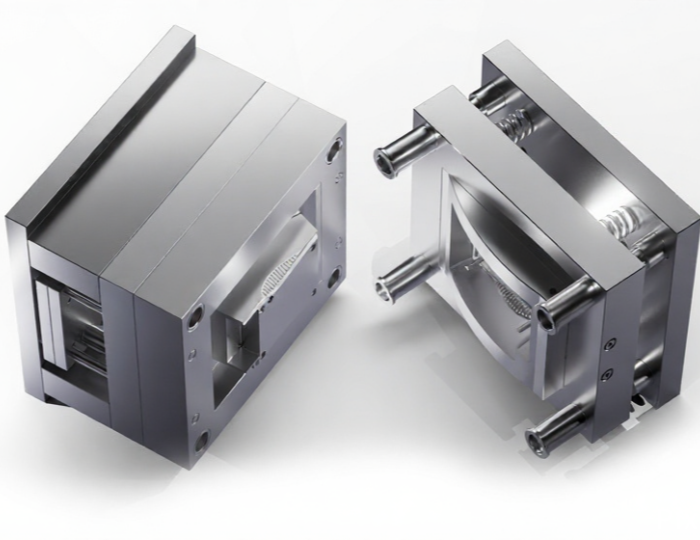

Plastic Injection Molding

High-precision plastic injection molding for EV battery housings, connectors, and structural components.

Rubber Injection Molding

Rubber injection molding for seals, gaskets, and elastomer parts ensuring airtight, liquid-tight performance in harsh new energy environments.

CNC Machining

CNC machining for high-accuracy new energy components, prototypes, and low-volume parts with tight tolerances and complex geometries.

Insert Molding

Insert molding integrates metal inserts with plastics for reinforced connectors and conductive components used in batteries and charging systems.

Why Choose Livepoint

Engineered for reliability, scalability, and risk-free manufacturing across demanding new energy applications.

- Certified Quality Assurance

Our in-house quality laboratories include CMM inspection, CT scanning, and electrical performance testing, ensuring every component meets stringent safety, reliability, and automotive-grade quality standards (IATF 16949 certified).

- High-Volume Manufacturing

With advanced injection molding machines and fully automated production cells, we deliver stable, efficient, and cost-effective manufacturing to support long-term, high-volume new energy programs.

- Advanced Engineering

Using Moldflow simulation and engineering-driven design, we proactively eliminate risks related to thermal, electrical, and structural performance, ensuring long-term durability of critical new energy components.

500 Million

Parts Manufactured

200+

Customers Served

95%

of Leading Brands Served

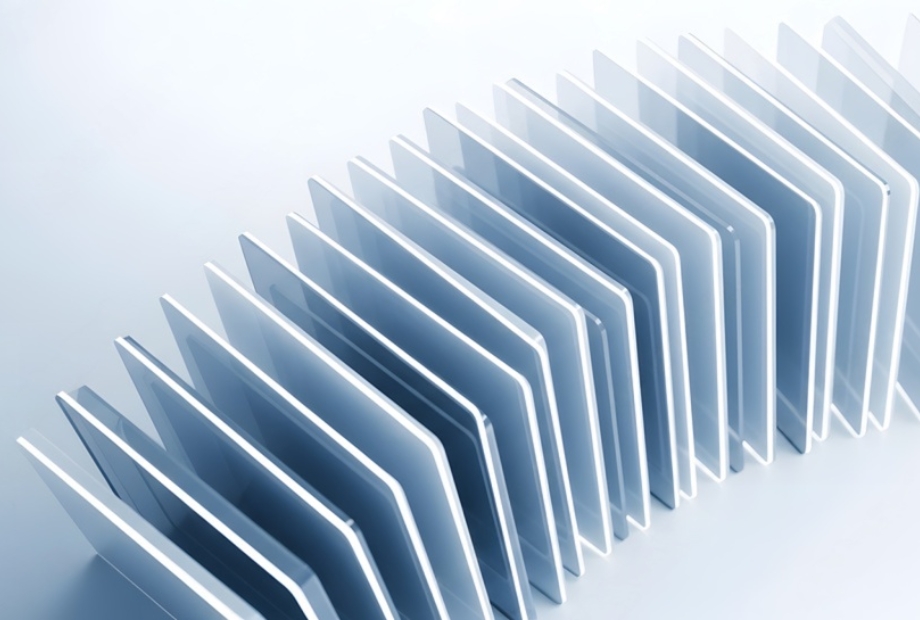

New Energy Parts We Can Manufacture

We manufacture high-performance plastic and composite components for critical new energy systems, supporting safety, reliability, and long-term operation across demanding applications.

Electric Vehicles (EVs)

Battery housings & cell holders, busbar insulators & connectors, thermal management components, powertrain sensor housings & insulation, charging gun housings & socket assemblies, interior & exterior lightweight parts

Energy Storage Systems (ESS)

Battery module enclosures, thermal management parts, structural support components

Hydrogen Fuel Cells

Bipolar plates, sensor housings, fluid management components

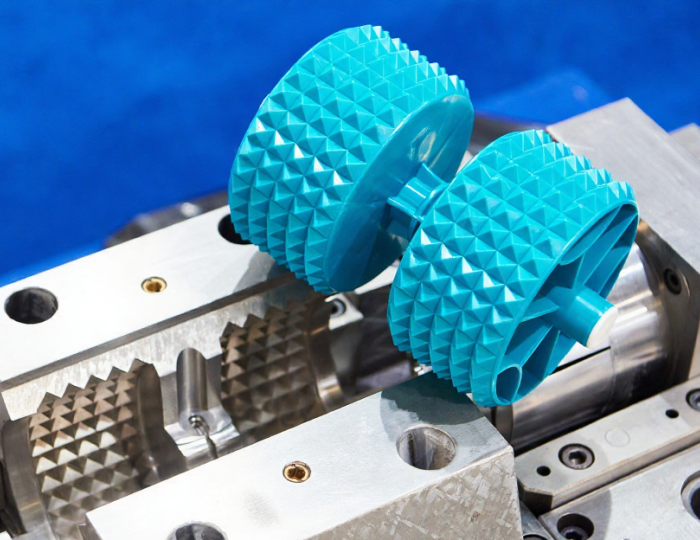

Solar & Wind Power

Junction boxes & connector housings, sensor protectors, internal durable gears

Materials for New Energy Parts

We support automotive projects with application-specific material selection to meet mechanical, thermal, and regulatory demands.

PPS

High-temperature resistant, chemically stable polymer ideal for EV battery housings, powertrain components, and demanding thermal management applications.

PPA

Exceptional mechanical strength and heat resistance, perfect for structural components exposed to high temperatures and chemical stress.

PEI

Lightweight, flame-retardant, and dimensionally stable material suitable for insulating parts, connectors, and high-performance interior components.

V-0 Rated Nylons

Flame-retardant nylon grades meeting UL94 V-0 standards, widely used for electrical insulation, housings, and connectors.

PC

Durable and transparent, ideal for protective covers, lenses, and interior or exterior components requiring high impact resistance.

LFT

Reinforced thermoplastics delivering superior stiffness, strength, and dimensional stability for structural parts in EV and energy storage systems.

1th Floor, Building C, Hengshunyuan Industrial Park,No. 6, Louyi Road, Loucun Community, Xinhua Street, Guangming District, Shenzhen City, Guangdong Province, China

Energy Industry Injection Molding FAQs

Absolutely. We engineer parts to meet electrical insulation, thermal management, and chemical resistance requirements specific to new energy systems.

We select high-performance polymers with UL94 V-0, CTI, and HDT ratings, optimize mold flow, and maintain controlled environments to prevent failures.

We apply robust DFM, optimize gate and cooling designs, and perform long-term performance testing to prevent deformation, cracking, or failure.

We validate materials for chemical resistance and apply protective coatings or finishes to enhance UV and environmental durability for demanding applications.

We design integrated sealing grooves and gasket interfaces, maintaining ultra-stable process conditions for consistent sealing in high-volume production.

Full automation, in-line vision inspection, real-time SPC, and proactive tooling maintenance guarantee consistent quality, color, and dimensional stability.

Our processes comply with IATF 16949 and ISO 9001, supported by in-house QC labs including CMM, CT scanning, and electrical testing equipment.

Yes. Our engineering team helps select materials to optimize strength, heat resistance, flame retardancy, and manufacturability for your components.