Industrial Components Injection Molding & Manufacturing

High-volume, high-precision injection molding for plumbing, toys, household, and industrial components, delivering exceptional quality from concept to production.

- IATF 16949 & ISO 9001:2015 certified

- 24/7 engineering support

- 23+ years in precision tooling

Why Choose Livepoint

Delivering precision, reliability, and excellence across every project, from concept to high-volume production.

- Proven Expertise

Decades of combined experience across multiple industries ensure we understand your challenges and deliver solutions that meet exacting standards.

- Quality as Standard

Our ISO 9001 & IATF 16949 certified system ensures every batch meets strict specifications, with full SPC reports and first-article inspections.

- Precision Production

Advanced machinery and automated systems enable consistent, high-precision parts with exceptional efficiency, even for complex or large-scale projects.

500 Million

Parts Manufactured

200+

Customers Served

95%

of Leading Brands Served

Industrial Components We Manufacture

We produce critical components engineered for reliability, precision, and long-term performance across diverse industrial applications.

Robust components designed for pressure, temperature, and corrosion resistance:

- Pipe Fittings (Elbows, Tees, Couplings)

- Valves & Faucet Components

- Pump Housings & Impellers

- Connectors & Seals

- Custom Plumbing Solutions

Reliable, safe, and creative parts for imaginative designs:

- Action Figure & Doll Parts

- Building Block Components

- Wheels, Gears & Moving Parts

- Electronic Toy Housings

- Outdoor Play Equipment Parts

Functional, durable, and aesthetically pleasing components:

- Kitchenware & Appliance Housings

- Storage Container Lids & Bases

- Personal Care Product Housings (e.g., electric toothbrushes, razors)

- Cosmetic Cases & Components

- Furniture Parts & Hardware

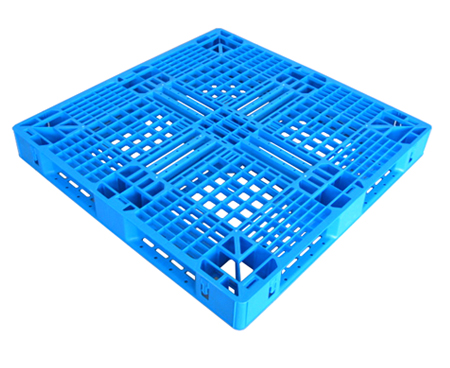

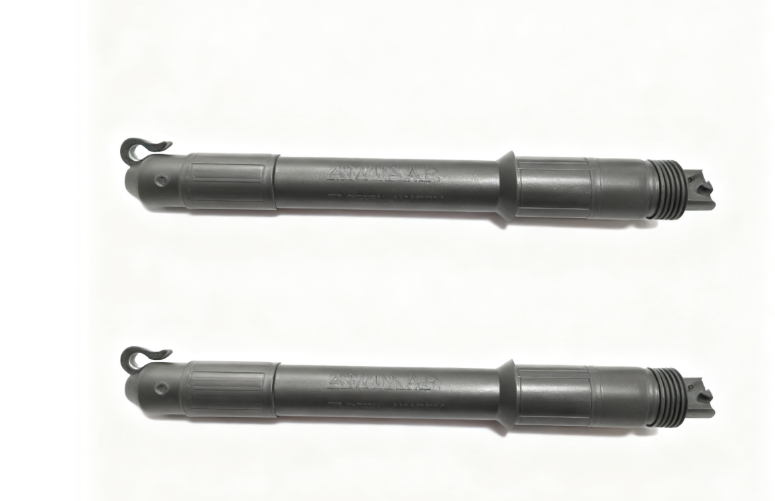

High-tolerance, robust parts for industrial applications:

- Enclosures & Housings

- Gears, Rollers & Guides

- Connectors & Assemblies

- Custom Machine Components

- Material Handling Parts

High-precision parts meeting thermal, optical, and durability demands:

- LED Lenses & Optical Components

- LED Housings & Enclosures

- Thermal Management Solutions

- Assembly & Structural Components

Ultra-high voltage applications requiring reliability and precision:

- Insulating Parts

- Housings

- Connectors

Our Expertise in Industrial Parts Manufacturing

Delivering precision-engineered components for plumbing, toys, household, industrial, LED, and UHV applications with unmatched quality, durability, and performance.

Plumbing & Fluid Handling Components

Material Expertise

PP, POM, and Nylon are selected for chemical resistance, pressure endurance, and long-term reliability.

Perfect Sealing

Precision molds ensure leak-proof performance from first part to millionth.

Durability Certified

Components validated for stress, UV exposure, and long-term operational stability.

Toys & Recreational Products

Uncompromising Safety

Fully compliant with ASTM F963, EN-71, and other international toy safety standards.

Vibrant Aesthetics

Color matching, high-gloss or textured finishes, and precise de-molding for intricate designs.

Durability for Play

Parts engineered to withstand repeated impacts and rigorous play conditions.

Household & Consumer Goods

Ergonomic Design Support

Optimized for user comfort, intuitive handling, and functional reliability.

Aesthetic Excellence

Premium surface finishes for visually appealing, high-quality products.

Cost-Effective Production

Efficient mold design and high-volume manufacturing maximize profitability.

Industrial & Technical Components

High-Tolerance Molding

Maintains tight tolerances for critical-fit industrial applications.

Engineering-Grade Materials

Expertise in filled polymers, high-temperature resins, and specialty engineering plastics.

Consistency & Traceability

Full documentation and lot traceability ensure repeatable quality across production runs.

Critical Components for LED

Precision Light Management

Optical components molded for flawless finishes and perfect light distribution.

Thermal Control

Advanced thermally conductive plastics safeguard LED longevity and heat performance.

Reliable Assembly

Structural and housing components engineered for durability and performance.

UHV & High-Voltage Infrastructure Components

High-Precision Mold Design

Complex, high-cavitation molds with ultra-tight tolerances for insulators, bushings, and housings.

Advanced Material Expertise

High-temperature plastics (PEEK, PEI, PPS, PSU), flame-retardant nylons, polycarbonates, and thermosets.

Controlled Environment Manufacturing

Cleanroom molding prevents contamination and ensures dielectric integrity.

1th Floor, Building C, Hengshunyuan Industrial Park,No. 6, Louyi Road, Loucun Community, Xinhua Street, Guangming District, Shenzhen City, Guangdong Province, China

Industrial Component Injection Molding FAQs

We produce high-precision parts for plumbing, toys, household goods, LED components, UHV infrastructure, and custom industrial applications.

Our expertise includes engineering-grade polymers such as PP, POM, Nylon, PEEK, PEI, PPS, PSU, polycarbonate, and flame-retardant specialty materials.

We provide DFM analysis, rapid prototyping, and full mold engineering to optimize designs for manufacturability, performance, and cost-efficiency.

Yes. Our modern automated machinery, production cells, and quality control systems ensure scalable, efficient, and consistent high-volume manufacturing.