Injection Molding Service

in China

Fast, cost-efficient injection molding services in China, from prototyping to full-scale production, trusted by over 200 companies worldwide. Share your design for a free quote!

- T1 samples in as fast as 2 weeks

- ISO 9001:2015 & IATF 16949:2016 certified

- 100+ plastic & rubber material options

- No MOQ

Start An Injection Molding Quote

Supports: STEP | STP | STL | IGS | IGES | PRT | SLDPRT | SAT | X_T

- All information is secure and confidential.

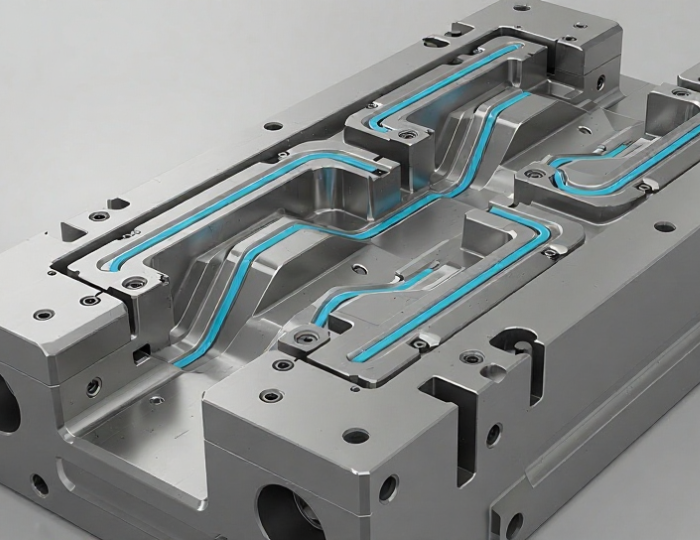

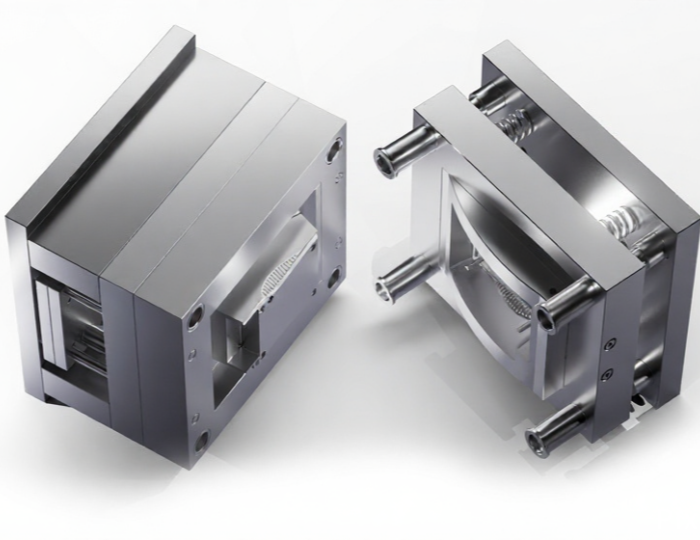

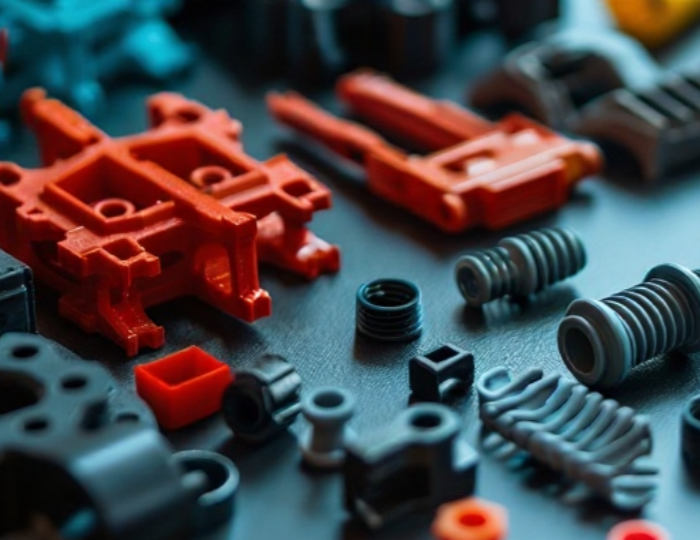

Our Injection Molding Services

Plastic Injection Molding

High-precision plastic molding for parts of all sizes, supporting prototypes to mass production with consistent quality & tight tolerances.

Rubber Injection Molding

Durable rubber molding solutions designed for components requiring flexibility, heat resistance, and long-term performance.

Insert Molding

Combines metal or pre-formed inserts with plastic in a single molding cycle to create stronger, more reliable, and cost-efficient assemblies.

Micro Injection Molding

Ultra-precision molding for miniature components with complex geometries, ideal for electronics, medical devices, and high-tolerance applications.

Multi-cavity Molding

Multiple cavities running simultaneously to deliver high-volume production with lower per-unit cost and consistent repeatability.

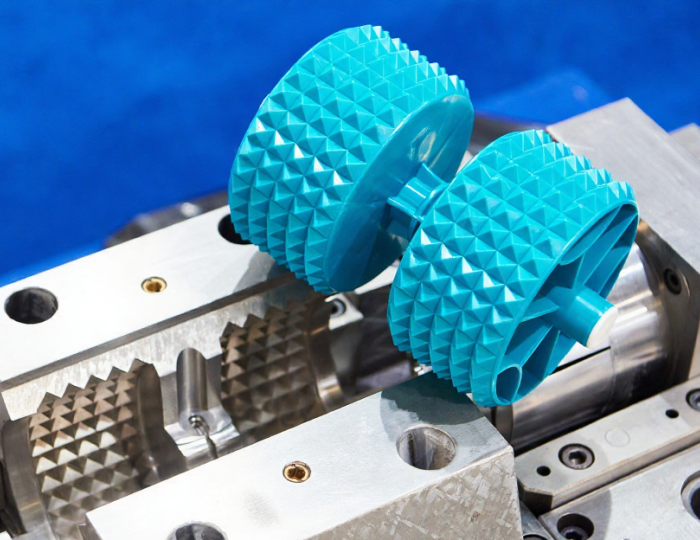

Two-shot/Multi-shot molding

Two or more materials molded in one process to create integrated, multi-color, or multi-material parts without secondary operations.

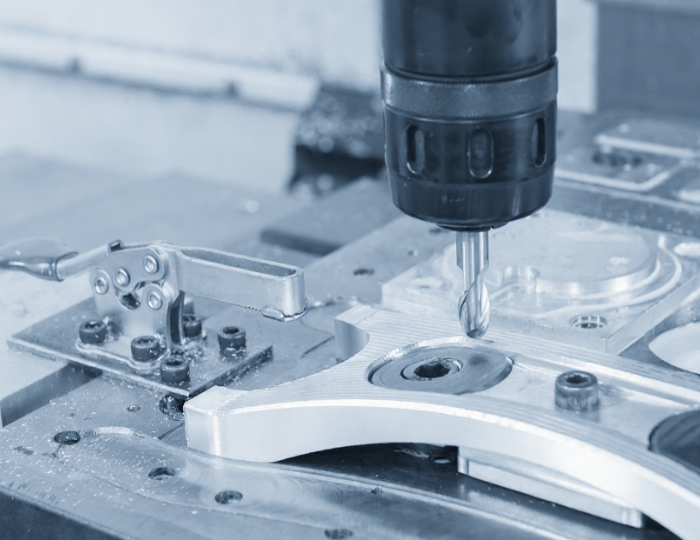

Why Choose Livepoint

Partner with Livepoint, a leading injection molding supplier in China, for fast turnaround, transparent communication, and consistently dependable quality throughout your product journey.

- One-Stop Convenience

From custom mold tooling to full-scale part production, we streamline your entire manufacturing workflow.

- Expert Guidance

We provide DFM insights, material selection support, and process optimization to improve part performance and reduce production risks.

- Strict Quality Control

Comprehensive quality checks, including in-process inspections, CMM measurement, and final functional testing, ensure consistent and dependable quality.

100K+

Parts/ Month

30+

Injection Machines

100-800 Ton

Press Range

Customer Success Cases

Discover how global brands achieve success through our end-to-end manufacturing expertise.

World's First UHV Hybrid Insulator

Partnered with top Chinese universities, Livepoint manufactures 70-year reliable UHV hybrid insulators with high-volume efficiency, combining patented molds, custom machines, and innovative solid-state injection to transform lab concepts into industrial-scale power grid solutions.

>95%

mass-production yield

50-60%

faster molding cycles

15.81 kN/m

tear strength

High-Precision Pipes for Infrastructure Projects

Livepoint partnered with Poland’s top distributor to provide high-precision plastic pipes for large-scale government water infrastructure projects. Using patented core-pulling and arc mold technologies, we ensured efficient production, flawless demolding, and durable, leak-proof pipes for municipal and industrial use.

±0.15 mm

dimensional tolerance

>300,000

units produced

30%

faster cycle time

How to Work with Livepoint

Upload Your File

Share your design files (CAD, STEP, IGES) and project requirements.

Get Quote & DFM

Receive a customized quotation along with a detailed DFM report.

Confirm T1 Sample

Approve T1 molded samples for dimensions, fit, and performance.

Production Starts

Move your project into full-scale manufacturing after approval.

Parts Delivered

Your parts are inspected, packaged, and shipped on time.

Injection Molding Materials

We offer a wide selection of engineering plastics and rubber materials to match your part’s performance, durability, and cost goals. Contact us for more material options.

ABS

A widely used engineering plastic offering strong impact resistance, good toughness, and stable dimensional performance. Ideal for enclosures, structural housings, consumer products, and functional prototypes.

- Color:

- Price:

- Lead Time:

Natural, black, white, custom

$$

About 5 business days

PA

A strong, abrasion-resistant material offering great mechanical toughness and thermal stability, commonly used in industrial components, automotive parts, and structural applications.

- Color:

- Price:

- Lead Time:

Natural, black, custom

$$

About 5 business days

PBT

A reliable engineering resin with excellent electrical insulation, heat resistance, and dimensional accuracy. Ideal for automotive housings, connectors, and high-precision molded components.

- Color:

- Price:

- Lead Time:

Natural, black, custom

$$

About 5 business days

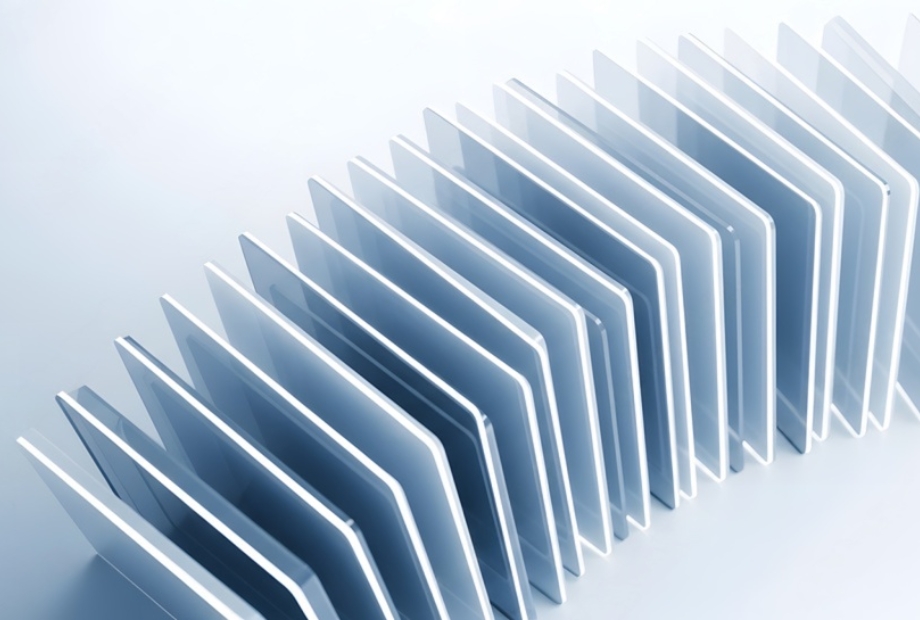

PC

A high-performance resin known for exceptional impact strength, heat resistance, and optical clarity, commonly used for protective covers, lighting components, and mechanically demanding parts.

- Color:

- Price:

- Lead Time:

Transparent, black, custom

$$

About 5 business days

PE

Lightweight and chemically resistant, suitable for functional components, containers, and flexible parts requiring low moisture absorption and good impact strength.

- Color:

- Price:

- Lead Time:

Natural, black, custom

$$

About 5 business days

PMMA

Features excellent transparency, surface hardness, and weather resistance, making it suitable for lens components, display panels, and parts requiring long-term optical stability.

- Color:

- Price:

- Lead Time:

Transparent, translucent, custom

$

About 5 business days

POM

Provides high stiffness, low friction, and excellent dimensional stability—ideal for gears, sliders, precision mechanisms, and components requiring smooth, wear-resistant movement.

- Color:

- Price:

- Lead Time:

Black, white, custom

$$

About 5 business days

PP

Offers outstanding chemical stability, fatigue resistance, and flexibility, making it ideal for consumer goods, living hinges, medical components, and lightweight structural parts.

- Color:

- Price:

- Lead Time:

Natural, black, custom

$

About 5 business days

Silicone

- Color:

- Price:

- Lead Time:

$$

About 5 business days

Injection Molding Surface Finishes

Enhance the appearance, texture, and functionality of your injection-molded parts with a wide range of finishing options.

As Molded

Description

Parts come directly from the mold without additional processing, showing the natural texture and gloss level defined by the tool steel and machining quality. Ideal for functional prototypes and cost-sensitive applications.

Advantages

- Most cost-effective finish

- Fastest lead time

- Consistent surface defined by mold quality

SPI Finished

Description

A standardized mold polish system (A1–D3) that defines different gloss levels, from optical-grade high polish to controlled matte textures—ensuring predictable appearance and mold consistency.

Advantages

- Industry-standard classifications

- Reliable surface repeatability

- Supports glossy, semi-gloss, and matte finish needs

Polishing

Description

Mechanical polishing enhances smoothness and visual clarity while reducing surface defects, weld lines, and minor imperfections. Ideal for aesthetic products and parts requiring better transparency.

Advantages

- Higher surface shine

- Removes minor tool marks

- Improves part cleanliness

Silk Screening

Description

A printing technique that applies logos, icons, labels, and patterns onto molded parts using mesh-based ink transfer, suitable for branding and durable graphic applications.

Advantages

- Customizable colors and patterns

- Affordable for medium–high volumes

- Strong adhesion for most plastics

Pad Printing

Description

A flexible printing method using a silicone pad to transfer fine graphics onto complex shapes, enabling detailed logos, symbols, and text on small or curved parts.

Advantages

- High detail accuracy

- Suitable for uneven/curved surfaces

- Stable printing quality

Glossy

Description

A high-shine surface created through mold polishing or specific processing, offering a premium appearance commonly used for consumer electronics, panels, and display components.

Advantages

- Premium, high-end appearance

- Enhances color saturation

- Smooth and reflective surface

Matte

Description

A low-gloss, texture-controlled finish that reduces glare and fingerprints, creating a clean, modern look ideal for durable consumer products and industrial parts.

Advantages

- Hides fingerprints and scratches

- Minimal reflections

- Stable, uniform appearance

Painting

Description

A post-molding coating process that applies durable color, texture, or protective layers to enhance appearance and surface strength for cosmetic or branding requirements.

Advantages

- Unlimited color options

- Improves wear and scratch resistance

- Adds texture or gloss variations

Etching

Description

Chemical or laser-powered etching creates micro-textures directly on the mold surface, producing patterns, grains, or tactile effects that replicate leather, matte patterns, or functional textures.

Advantages

- Deep, durable texture

- Large variety of texture patterns

- Hides flow lines and imperfections

Laser Engraving

Description

A precise marking process using focused laser beams to engrave permanent logos, serial numbers, QR codes, or patterns onto molded components without affecting structural integrity.

Advantages

- Permanent, wear-resistant marking

- Extremely high accuracy

- No inks or chemicals needed

Injection Molding Design Guidelines

Follow proven design principles to ensure manufacturability, reduce defects, and optimize cost, quality, and part performance in injection molding projects.

Features

Description

Wall Thickness

Maintain uniform wall thickness to prevent warping, sink marks, and uneven cooling. Typical range for common thermoplastics like ABS/PC is 1–3 mm, though this varies based on part size and material properties. Optimized thickness improves structural integrity and reduces material waste.

Draft Angle

Apply adequate draft angles (typically ≥1–2°) on vertical faces to ease part ejection and extend mold lifespan. Deeper draws or textured surfaces may require greater draft angles.

Ribs & Bosses

Reinforce parts with ribs and bosses without increasing wall thickness. Proper rib-to-wall ratios (typically 0.4–0.6× wall thickness) reduce stress and distortion while maintaining lightweight structures.

Corners

Use rounded corners (radius ≥ 0.5× wall thickness) instead of sharp edges to reduce stress concentration, improve material flow, and minimize sink marks or cracking.

Undercuts

Minimize undercuts where possible, or implement side-actions/sliders for complex geometries. Reducing undercuts simplifies mold design, decreases cycle time, and maintains dimensional accuracy.

Tolerance

Set realistic tolerances based on material properties and process capabilities. Typical achievable tolerances for precision injection molding:

±0.05 mm for critical features

±0.1 mm for general features

1th Floor, Building C, Hengshunyuan Industrial Park,No. 6, Louyi Road, Loucun Community, Xinhua Street, Guangming District, Shenzhen City, Guangdong Province, China

Injection Molding FAQs

Plastic pellets are melted, injected into a steel mold under high pressure, cooled, and then ejected as a solid part. The cycle repeats quickly, enabling fast, consistent, and cost-efficient mass production.

China offers competitive pricing, faster tooling lead times, mature supply chains, and extensive engineering expertise. Custom injection molding manufacturers like Livepoint combine high-precision tooling, automated production, and strict QC to ensure global-standard quality.

Costs depend on part complexity, mold design, materials, surface finish, and production volume. Simple molds may start at a few thousand dollars, while complex, multi-cavity tools cost more. Per-unit costs decrease significantly with higher volume.

Custom injection molding offers a powerful combination of high precision, material versatility, and cost efficiency for medium- to high-volume production. It can create complex geometries with consistent quality and supports a wide range of engineering plastics tailored to mechanical, thermal, or aesthetic requirements.

However, the process also comes with certain limitations. The upfront investment in mold fabrication can be substantial, and design changes after tooling is made may lead to additional cost and delays. Production is highly efficient once the mold is finalized, but it is less flexible for very low-volume or rapidly changing designs.

Despite these challenges, custom injection molding remains one of the most reliable and scalable manufacturing solutions for durable, repeatable plastic parts.

Yes. Once your mold is built, you can reorder at any time with no additional tooling cost, unless design changes are required or normal wear requires refurbishment.

No. Livepoint offers free mold storage for our customers. Your molds remain securely maintained and ready for repeat production whenever you need them.