Medical Device Injection Molding & Manufacturing

We manufacture high-precision, mission-critical medical components — from surgical instruments and drug delivery systems to diagnostic equipment housings — ensuring consistent quality, tight tolerances, and regulatory-ready production.

- ISO 9001:2015 certified

- 24/7 technical support

- 23+ years in precision tooling

Medical Device Parts Manufacturing Capabilities

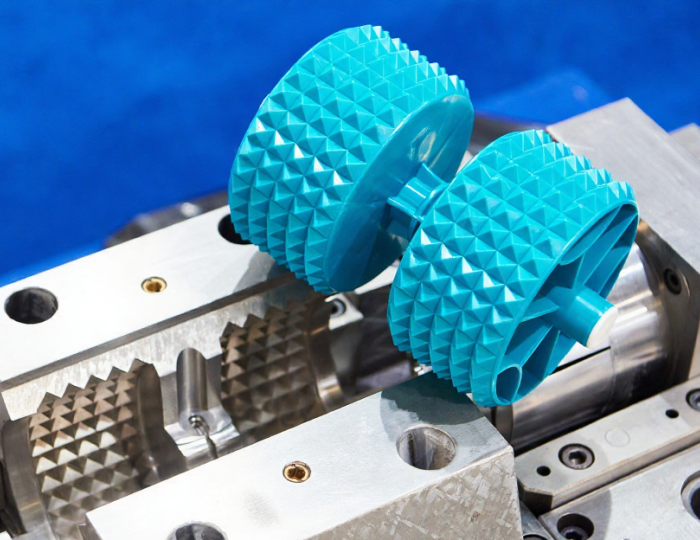

Plastic Injection Molding

Precision medical injection molding for high-volume, repeatable production of mission-critical components using medical-grade materials.

Rubber Injection Molding

Cleanroom-capable rubber injection molding for seals, gaskets, and elastomer components requiring reliability and biocompatibility.

CNC Machining

Our CNC machining supports complex medical components, tight tolerances, and low-to-medium volume production requirements.

3D Printing

Industrial 3D printing enables rapid validation builds, design iteration, and low-volume medical part production.

Why Choose Livepoint

We deliver precision, compliance, and reliability for custom medical components across regulated global markets.

- Reliable, Compliant Manufacturing

Our ISO 9001–certified processes (ISO 13485 underway) provide full traceability and support FDA, EU MDR, and other regulatory standards, ensuring your products are manufactured safely and meet all compliance requirements.

- Superior Medical Materials

We specialize in medical-grade polymers—including biocompatible, radiopaque, and high-temperature resins—delivering safe, durable, and precise components for demanding clinical and diagnostic applications.

- Controlled, Cleanroom Production

Our Class I–III cleanroom molding minimizes contamination and maintains strict environmental control, giving you confidence that every part is patient-safe and regulatory-ready.

500 Million

Parts Manufactured

200+

Customers Served

95%

of Leading Brands Served

Medical Parts We Can Manufacture

We partner with medical device manufacturers to produce a wide range of essential components, including:

- Surgical instrument housings

- Ergonomic medical handles

- Transparent diagnostic lenses

- Precision internal gear components

- Robotic surgery system parts

- Diagnostic equipment housings

- Inhaler components

- Auto-injector parts

- Insulin pen components

- IV set components

- Single-use connectors

- Medical stopcocks

- Fluid collection chambers

- Disposable medical trays

- Biocompatible implant components

- Orthopedic trial parts

- Non-active implant housings

- Pipette tips

Materials for Medical Parts

Choosing the right material is critical for the safety, efficacy, and longevity of medical devices. Here are some of the most trusted materials used in medical injection molding and their key applications.

ABS

Ideally suited for non-implantable medical equipment housings, enclosures, and durable components that require structural integrity.

PC

A top choice for transparent medical components, such as surgical instrument lenses, flow meters, and housings for critical care devices.

PE

Suitable for single-use medical packaging, bottles, containers, and disposable products where sterility and cost-effectiveness are paramount.

PU

Extensively used in critical applications like medical tubing, catheters, wound care products, and certain short-term implantable devices.

Silicone

Silicone is the material of choice for high-performance medical tubing, seals, gaskets, soft-touch components, and long-term implants.

NBR

Its applications include examination and surgical gloves & specific seals and diaphragms that may encounter oils or hydrocarbons.

EPDM

Commonly specified for autoclavable seals, gaskets, and valve components that must maintain resilience through numerous sterilization cycles.

Fluoroelastomers

FKM elastomers are essential for components exposed to aggressive chemicals, fuels, or high-temperature fluids to ensure reliability.

1th Floor, Building C, Hengshunyuan Industrial Park,No. 6, Louyi Road, Loucun Community, Xinhua Street, Guangming District, Shenzhen City, Guangdong Province, China

Medical Injection Molding FAQs

Our medical manufacturing processes operate under an ISO 9001–certified quality management system. We are actively preparing for ISO 13485 certification and support project-specific requirements aligned with FDA and EU MDR regulations, including full traceability and documented process control.

Yes. We offer cleanroom-controlled injection molding for medical components that require strict particulate and contamination control, supporting Class I, II, and III medical device applications.

Yes. We support medical projects from early validation and pilot builds through scalable, high-volume injection molding, ensuring consistency, reliability, and a smooth transition into production.

Yes. We provide pilot and validation builds using production-intent materials and controlled processes, enabling functional testing, design verification, and performance evaluation before full-scale manufacturing.